I’ll hand it over to Brent now to explain the floor coating process because I got out of all the work on this project. I had my own labor intensive project – taking care of a newborn! Since it was a two person job my dad was nice enough to sub in for me and give Brent a helping hand. Yes, the other person in the video is my dad, not me. Pregnancy changed my body but not THAT much.

STEPS

Part 1: Repairing the Concrete Slab

1. Before applying any of the garage floor coating products there were a few large craters that needed to be filled with concrete.

We used a mallet and cold chisel to square the edges of the craters to be 1/2″ deep. This allowed the edges of the cement patcher to be applied thick and avoid chipping.

2. We followed the instructions on the cement patcher product.

To mix it up we added water to the powder mix. The concrete mixed to a thicker consistency than I expected.

3. Using a spray bottle, we wet each crater so the cement patcher would adhere to it.

After filling each hole, we used a finishing trowel to smooth the surface.

4. To level the slab, we rented a concrete grinder from a home improvement store.

We started grinding down all the high spots. This also revealed the cracks around the foundation repair that needed to be patched before applying the concrete floor coating.

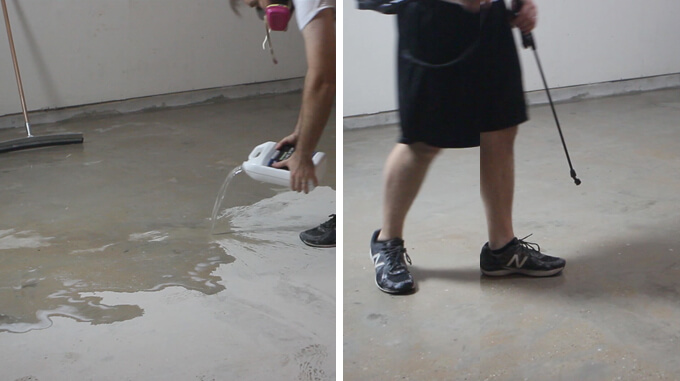

5. After leveling the entire floor surface, we sealed the floor with Rust-Oleum’s RockSolid Moisture Stop.

The moisture stop product created a barrier within the concrete by filling the pours within the slab.

Once the entire slab was saturated, I misted the surface with water to keep it wet for 45 minutes. After the floor dried, I rinsed it with water and scrubbed it to remove any efflorescence from the surface.

6. The floor took about two days to dry out before we repaired any of the cracks and small divots with Rust-Oleum’s Fast Patch product.

We mixed equal parts A and B of the fast patch mix and spread it over the surface with a puddy knife.

The divots deeper than 1/2″ took 2 applications.

Part 2: Applying Rust-Oleum RockSolid Floor Coating

Almost everything comes in the box to apply the RockSolid floor coating.

The only additional supplies needed was the:

7. After setting out all the bags of coating we checked that that there were no clumps and then started by mixing one bag.

The two part product mixed in the bag by rolling side B into side A breaking the seam in the middle. We really like this feature because it allows the product to mix without introducing air. This allowed for a slightly longer working time.

8. We shook/mixed the product in the bag for three minutes before cutting it open and pouring it into a bucket. Then, we used a paddle mixer and drill to mix the metallic tint into the clear coating.

9. We used a paintbrush to apply the coating along the wall and rolled everything else.

The application is definitely a two person job. Luckily, Courtney’s dad came over to help since Courtney was tied up with our two week old son.

After spreading the product evenly using a M and W roll pattern, I came back with the a href=”https://amzn.to/32xucHt” target=”_blank”>roller and swirled the coating. We continued across the garage floor section by section mixing each kit as needed.

10. Grinding the floor did open some large pin holes in the floor that created a few bubbles during the application process.

We took a gamble and popped the bubbles. Luckily, all of the bubbles we popped leveled out and dried smooth.

I am really impressed with the work Brent and my dad did on the garage floor. Once it had all dried and the garage was empty, I happily danced around barefoot to show my approval of a job well done. I know it isn’t safe to work in the garage without shoes, but at least I could if I wanted to now and not end up with layers of dirt stuck to my feet.