How to build a wood herringbone countertop for our office cabinets.

We are back with part two of our office cabinets project and today we are sharing how we made our herringbone countertop. After spending quite a bit of time on the base of the cabinets, we were looking for an affordable and relatively easy solution for the countertop. We wanted it to contrast the gray base but still be interesting so a wood herringbone countertop worked out perfectly.

We should mention that this wood countertop is more for decorative purposes. We wouldn’t recommend this type of countertop anywhere where food is involved or as a work surface that would get a lot of hard use but in an office it looks amazing and works great.

How to Build a Herringbone Countertop

SUPPLIES

Shop the products we used for this project in one place.

- 2×4 Premium Kiln-Dried Whitewood

- Miter Saw

- Drill Press

- Drill

- 3-1/2 in. Tan Exterior Star Drive Wood Screws

- Face Clamp

- Wood Glue

- T-square

- Large Clamps

- Nail Gun

- Finishing Nails

- Orbital Sander

- Rust-Oleum Ultimate Wood Stain in Kona

- Wood Pine Molding

- Table Saw

- Painters Tape

FYI: This post contains a few affiliate links to products we used to make this project. Gray House Studio does receive commissions for sales from these links but at no extra cost to you. We appreciate you supporting this site. Read our privacy and disclosure policy. You can also easily shop our recommended products here.

In this video I will show the steps as well as the materials and tools necessary to make a wood herringbone countertop like we did for our office cabinets.

TUTORIAL VIDEO

Subscribe to our YouTube Channel

Like our video? Subscribe and help us reach our goal of 100k subscribers.

STEPS

To build our herringbone counter top we used 2×4 Premium Kiln-Dried Whitewood.

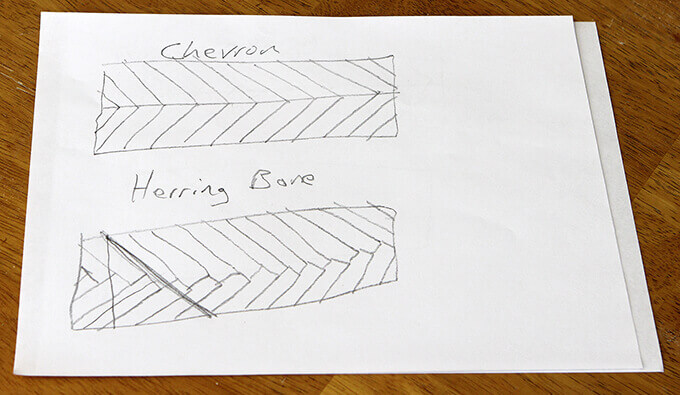

We chose to go with a herringbone pattern for our counter top but we needed a game plan to determine all of our measurements for the pieces before we started cutting.

In order to figure out the lengths of the boards we first needed to figure out the length of the 45 degree angle and then divide that by two which gave us the length of the center of each board.

One side of each board needed to be cut at a 90 degree angle and the other side needed to be cut at a 45 degree angle.

All the boards needed to be the same length so to get the distance we just took the depth of our counter top and determined the hypotenuse (there are calculators online to do that) and then we cut all the boards the same length with the miter saw.

We determined that the center of each board should be 13 ¾ inches so I took my measuring tape and marked that measurement on the center of the board. To double check that it is the center I measured the other way and made the mark.

I used the straightedge side of the board as my 90 degree angle. The 45 degree angle needed to intersect the center point I marked so I used a framing square and turned it until it showed 45 degrees and then slid it down the board until it met my mark.

Once it was on the mark I drew a line where I would cut the board on the miter saw.

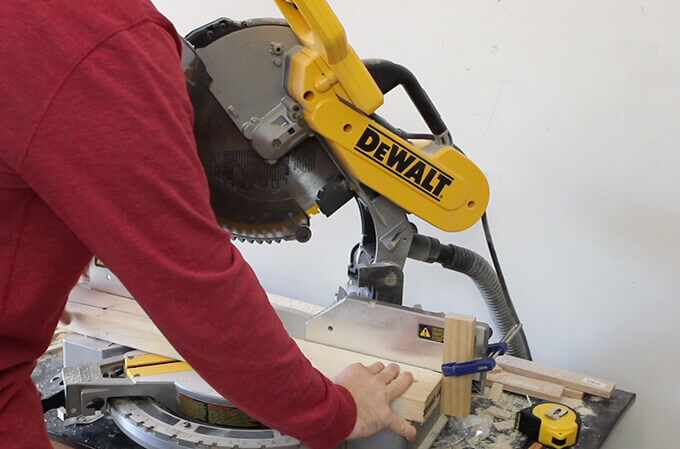

1. Once my first board was lined up for the cut on the miter saw, I used a scrap piece of wood and a clamp to make a stop so that all the following cuts would match and be exactly the same.

In between each 45 degree angle cut, I needed to cut another 90 degree angle cut so that I could turn the board and put the 90 degree angle cut against the stop to make the exact same 45 degree angle cut.

To do this I put a spacer board between my board so the actual 2×4 sat flush against the straight guard.

Then I changed the blade back to 90 degrees and I made the cut and then flipped the board around and continued making the 45 degree angle cut.

2. After all the boards were cut, I started the process of attaching them together.

I used a drill press to drill a hole in the side of each of the boards to countersink the screws.

3. I screwed pairs of boards together and then once they were all glued and screwed together I took all the “v” shapes that were created and screwed them together the same way all the way down until the counter top was completely joined together.

Normally, I would just butt the edges together and use wood glue. I would let the wood glue set up in a clamp and it would hold fine.

However, because these are cheap 2x4s I used and they had a bunch of knots in them, each of the boards might expand at different rates and it could make the seams come apart. The screws will make sure to keep all the pieces held together tight.

4. I used a T-square to mark each side indicating on all the boards where to cut them for a straight edge.

5. Once both sides of the counter top were cut to length square with the miter saw, I flipped all the boards over, lined them up, put wood glue in each of the seam and used large clamps to hold them together.

6. Then I used a nail gun to drive finishing nails through the sides of the boards going from one board to the next on each side and then through the bottom going from one board to the next across the seams.

If the boards are bowed after being screwed together, you can straighten the bow by facing the highest point of the center up and then placing the clamp on the boards and tighten it until the boards straighten.

7. I left the clamps on for a day or two while the glue dried and then used an orbital sander on the top surface of the countertop to remove any high points.

8. Once the surface was flat, we stained the countertop being careful to get the stain in all the cracks. We used our favorite stain, Rust-Oleum Ultimate Wood Stain in Kona.

9. Finally, before installing the countertop I used our table saw to cut sections of wood pine molding down to size to frame the countertop.

When the wood pine molding were cut to the correct size, I turned the boards on their sides and cut the edges straight.

10. After staining the frame, we installed the sections of the countertop on our cabinet base and glued the frame to the edge of the countertop.

11. We used painters tape to hold it in place while the glue dried.

Check out our finished office cabinets or how to build a cabinet drawer.

After we installed the herringbone countertop, we secured the cabinets to the wall.

We are really happy with how our wood herringbone countertop turned out. It looks great on top of the gray cabinets. Our next DIY project will be building a desk with the same Kona stain and a gray front piece.

Our home office is coming together nicely and we can’t wait to share the final reveal.

PIN FOR LATER